Details

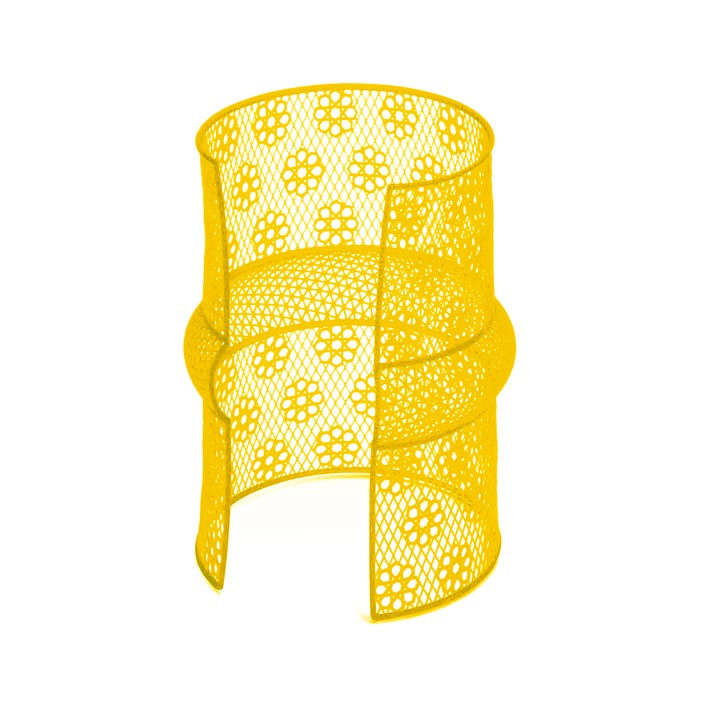

This is a scaled down model of a 3D printed Exhaust Manifold from an in-line 4 Cylinder engine. The exhaust gases from the engine are collected by the exhaust manifold before being sent to the catalytic converter. The exhaust manifold design affects the emission quality, fuel consumption and performance of an IC Engine. Several iterations may be needed to finalize a certain design. One of the quickest methods to manufacture prototypes for form and fit testing is SLA/DLP. This model was made on our Zeta Top Down DLP Printer at a 70 Micron Z-layer height.

Solid models such as these are especially challenging in traditional film based bottom-up resin 3D Printers. Our Top Down approach enables us to print this model with ease using minimal supports. Due to the lower usage of support structures, the part could be post-processed without hassle. This was a form and fit-testing model made in our GP LB (Low-Bending Prototyping) Resin. Our GP LB resin has one of the lowest shrinkage rates (<1.5%) of any 3D Printable material. The material also has a High Impact Strength giving the printed parts good durability and toughness. Based on customer requirements, we can also produce similar engineering models in our DC Wax Resin allowing users to manufacture their parts in a metal of their choice using Investment Casting.