Details

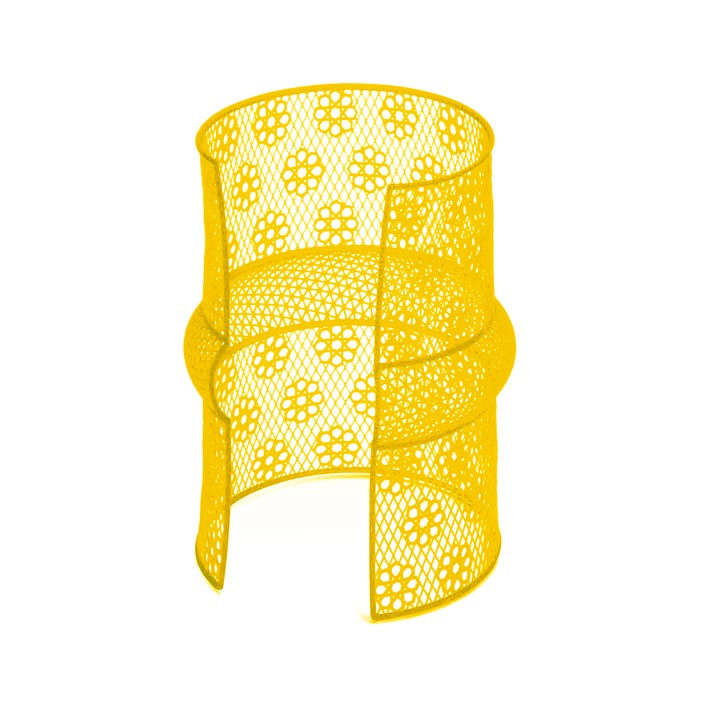

This 3D printed filigree Ring was printed on our Zeta Top Down DLP 3D Printer at a 35 Microns Z-Layer Height. Given the intricacy of this model, it was not possible to manufacture a RTV Silicone Mould for it. Therefore, the customer chose to get the model printed in our DC Wax Resin. This meant that the printed model could directly be used as a Wax Master pattern. Our Top Down Printer enabled the printing of this model with minimal supports thus ensuring that the intricate mesh structures do not get broken/ destroyed while post-processing. Unlike other Direct Castable resins, our DC Wax material has over 80% liquid wax content in the formulation.

High wax content photopolymers can only be printed in Top Down machines. Such materials can break easily while printing on traditional Film/ Vat Tray based SLA/DLP systems. Our DC Wax material starts melting at 350 degrees Celsius and has an ash-free burnout (at 750 degrees Celsius). This ensures that the minutest and most intricate details are preserved in the final casting and delivers porosity-free, clean results.