Material: PA-12 Nylon

Process: SLS

Finish: Epoxy Clear Coat

Lead Time: 5 days

Details

3D printing technology has come a long way in recent years, and one of the most advanced methods is selective laser sintering (SLS). This process involves using a laser to selectively fuse together fine particles of a polymer material, such as PA 12 nylon, to create a 3D object layer by layer.

One application of SLS 3D printing is in the production of back braces, which are used to support the spine and alleviate pain and discomfort caused by a variety of conditions. The use of PA 12 nylon in these braces is beneficial due to its high strength-to-weight ratio, good wear resistance, and low moisture absorption.

To create a 3D printed back brace using SLS and PA 12 nylon, the first step is to design the brace using computer-aided design (CAD) software. The design is then converted into a digital file that can be used by the 3D printer to create the actual brace.

During the SLS printing process, the 3D printer creates a thin layer of fine PA 12 nylon particles on a build platform. The laser then selectively fuses these particles together in the desired pattern, based on the digital file. This process is repeated layer by layer until the final product is complete.

One of the main benefits of using an SLS 3D printer to create a back brace is the ability to produce complex, customized designs with a high degree of precision. Traditional back braces are often limited in their design due to manufacturing constraints, but SLS allows for a greater degree of freedom in terms of shape and size. This means that a 3D printed back brace made using SLS and PA 12 nylon can be tailored to fit the unique contours of the wearer’s body, providing maximum support and comfort.

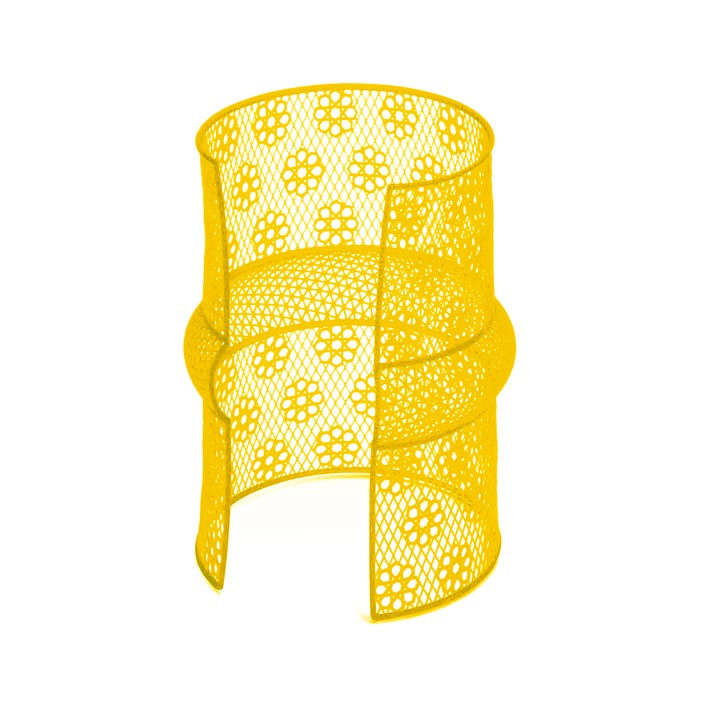

This Back Brace was made using SLS PA-12 with moisture-proofing. The back brace helps support patients undergoing treatment for Scoliosis. Scoliosis is a sideways curvature of the spine that is usually caused during adolescence. It affects 2-3% of the world’s population, so hundreds of millions of people deal with the sometimes-severe symptoms that come with it, from pain to indigestion. The back brace helps straighten the patient’s posture. Conventional Back Braces are also often ill-fitting and uncomfortable. Conventional orthoses, also require additional supporting elements.

Using SLS technology we can manufacture the back brace with a mesh structure making the brace breathable and reducing skin irritation. Variable stiffness at different regions can also be incorporated into the model based on amount of material deposited. The 3D Printed back brace also does not require any additional supporting elements and is made in a single piece. All such braces are fully customized and are made using 3D scans of the patient making a significantly more comfortable and effective product.