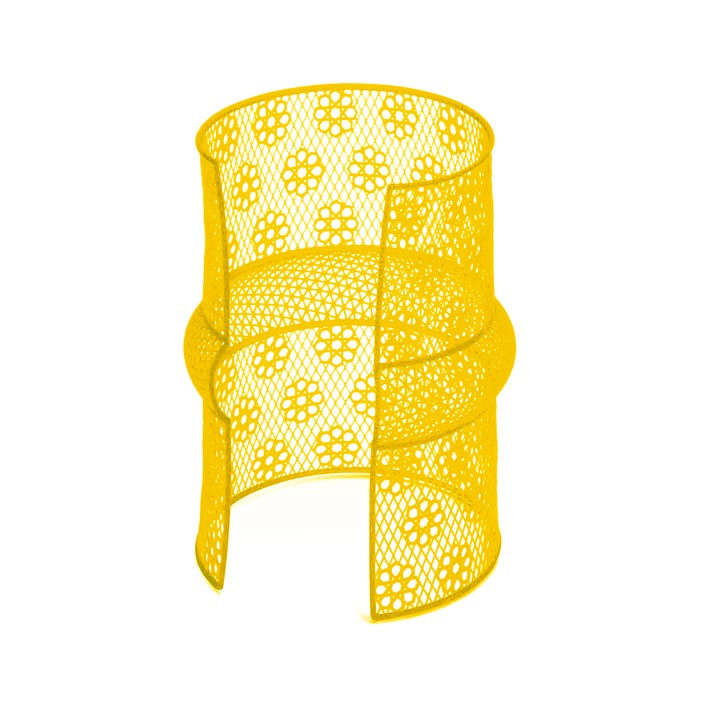

Material: PA-12 Nylon

Process : SLS

Finish : Epoxy Clear Coat

Lead Time : 4 days

Details

This is a scaled-down, representational model of a Rotary Engine from an airplane. The model contains moving parts and each of the pistons inside the cylinder block can be cranked using the handle. SLS (Selective Laser Sintering) technology enabled printing of this complex model without any support. Using SLS, this model could be made in a single build without requiring any assembly.

The challenge for this project was ensuring that the internal reciprocating parts were not fused with the cylinder walls. This meant that the machine print parameters had to be carefully optimized to ensure the tightest possible tolerances. Virgin PA-12 powder was used for this build to minimize print failure because of clumped powder. Another challenge was in the post-processing. Bead blasting is the most common post-processing method used to clean parts made on SLS Machines. Bead blasting also has the potential of destroying delicate moving models. Therefore, post-processing this model was a particularly tedious task requiring meticulous handling with extra precaution. An extra layer of clear epoxy was added to the outer fixed parts of the model to protect them from absorbing moisture.